Flight Monitor: Microsensors Bring Predictive Maintenance to Aircraft Cabins

Share

APEX Media: Embedded sensor technologies mean the inner workings of aircraft cabins may soon be monitored remotely – and in real time.

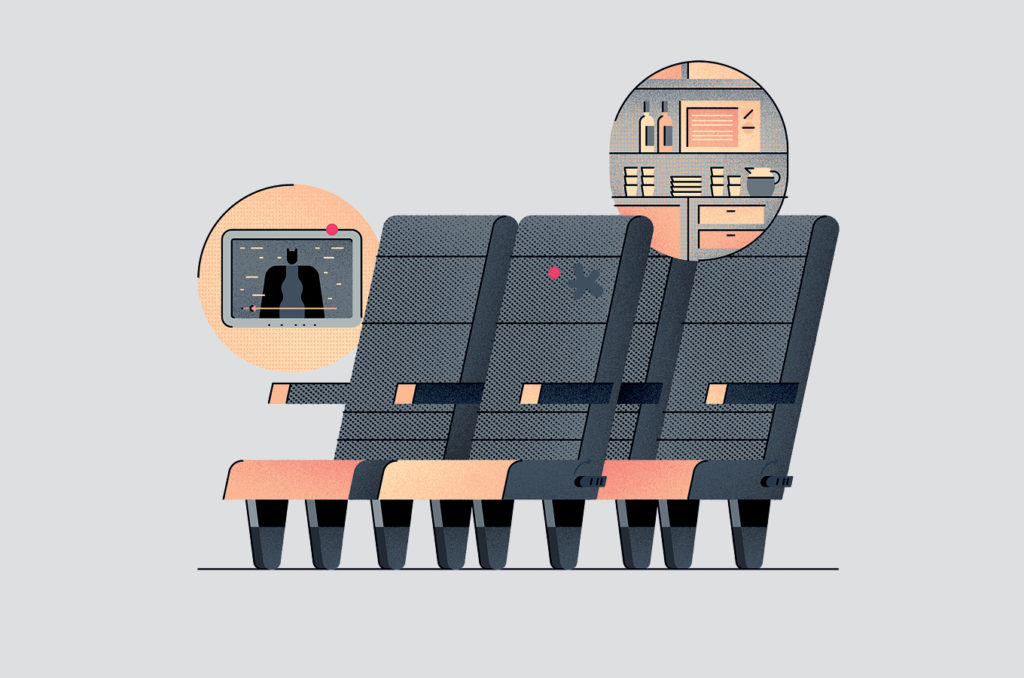

“In today’s world, passengers enter the cabin, take their seats and then detect that either the seat’s recline isn’t working, the seat fabric is dirty or the IFE [in-flight entertainment] doesn’t operate – and that means they have to change seats,” says Peter Schetschine, CEO of KID Systeme, explaining that the purpose of iCabin, a recently launched initiative, is to gather data from the cabin systems via sensors to make forecasts for maintenance purposes. “The clear advantage with predictive maintenance is that those things can be managed before the passenger gets on board,” he adds.

KID Systeme, an Airbus subsidiary, is one of the key stakeholders in the iCabin consortium, which pools the combined expertise of Bühler Motor, Diehl, Jeppesen and Zodiac, with associated partners Etihad Airways Engineering, Boeing, Baden-Württemberg university and the Hamburg University of Technology. Each participant brings competencies from their respective portfolios, ranging from actuation for seats, cabin management systems and connectivity to aircraft operations and integration.

“While engines of modern aircraft are equipped with multiple sensors, and enabled for remote health monitoring and predictive maintenance methods,” explains Bernhard Randerath, Etihad’s vice-president of Design, Engineering and Innovation, “the cabin itself is lagging behind this trend. Seat actuators, galley chillers or lavatory mechanisms aren’t monitored and networked in the same way.”

That’s where iCabin comes in. “iCabin will allow for the exchange of cabin system health and other in-service data between seats, galleys, lavatories and the cabin management system,” Randerath says, adding that doing so will allow for the application of predictive maintenance methods, resulting in operational cost reductions and improved passenger experience.

“The sensors are so small, they allow you to bring intelligence to fabrics,” – Peter Schetschine, KID Systeme

With the iCabin concept, microsensors would be placed throughout the cabin – each yielding relevant data for airlines. “You can embed microsensors into seat fabrics and determine if the passenger is in the seat or not, or sensors that indicate if seat covers need cleaning. The sensors are so small, they allow you to bring intelligence to fabrics. Or, when the seat belt sign is illuminated, you can check whether the buckle is locked, helping crew supervise,” KID’s Schetschine says.

Sensors can even be embedded into galley chillers, ovens and storage devices. “If you have better warehousing in the galleys, crew have a better idea of what is stored and they can react faster,” he adds.

Having just kicked off this April, and with a timeline stretching until March 2021, it’s still early days for iCabin, but David Voskuhl, vice-president of Communications and PR at Diehl Aviation, says, “You can expect savings of at least 30 percent, maybe even more in the later stage of the implementation. The target is a reduction of total ownership costs by creating a more standardized way of interlinking the involved items in the cabin.”

With major players on board, and a 3.9-million-euro backing from Germany’s Federal Ministry for Economic Affairs and Energy, airlines worldwide will surely be doing their own monitoring as this ambitious project gets underway.

Flight Monitor was originally published in the 8.4 September/October issue of APEX Experience magazine.