HAECO Develops Cabin Cargo Solutions in Response to COVID-19

Share

Since the onset of COVID-19, many airlines have transformed their aircraft cabins into makeshift cargo holds to transport important medical supplies and equipment around the world. APEX member HAECO saw this new requirement for flexibility in the cabin as an opportunity for innovation, and as such, has created a new range of products to accommodate both passengers and cargo in the same environment.

Within just four weeks, HAECO Cabin Solutions, a business unit of HAECO Group, has turned a concept for a range of new cabin interior cargo solutions into a viable product offering for both single-aisle and wide-body aircraft. The company has created four main deck stowage solutions, which airlines can mix and match within the cabin to suit their needs.

“We saw that airlines were starting to use passenger flights solely for cargo, and at the time we were beginning to see the need for social distancing, so we held a post-COVID-19 workshop focusing on what we could do to help airlines maintain revenue and optimize yields,” explained David Kelly, VP Marketing and Strategy, HAECO Americas. “We felt that if we could develop a solution where they could carry cargo and passengers simultaneously, this could help them optimize passenger vs cargo yield, use the cargo packages to distance passengers and maintain proper weight and balance requirements.”

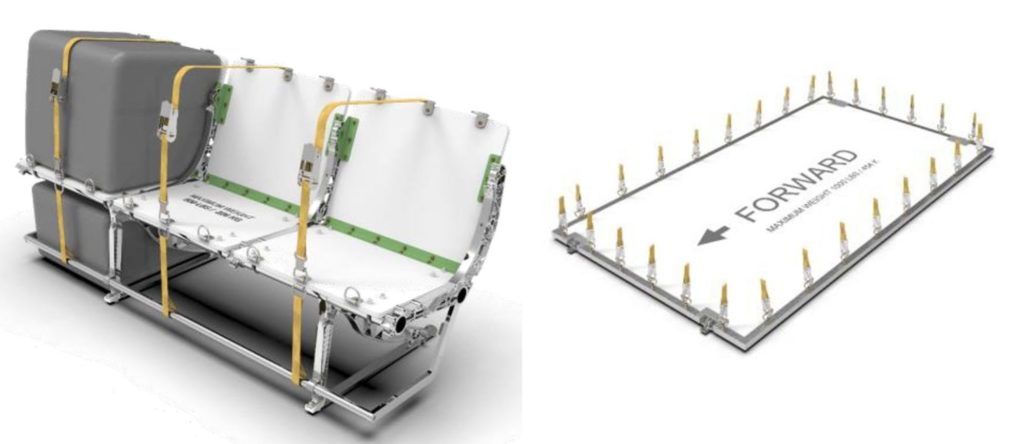

Airlines can opt for HAECO’s In-seat Stowage System, whereby boxes are placed on top of existing aircraft seating for passengers, with no reconfiguration required other than the introduction of easy to install frame-mounted strapping. Similarly, the Seat-Front Stowage System, which sees boxes stored on the cabin floor in front of a row of aircraft seating, offers a solution which can be quickly reversed as demand changes.

The All-in-One Package Stowage Device offers an optimized frame and tie-down system without a complete cargo conversion by securely transporting packages both above and below the airline’s existing seat track using custom fitted containers. Finally, there is a pallet stowage solution, which replaces multiple rows of aircraft seats.

“The primary benefit to our solutions is the amount of weight they can hold,” Kelly said. “The palletized version can hold 1000lbs, the all-in-one seat frame can hold 500lbs, and the seat and floor storage systems can hold 240lbs. This gives airlines specific load permissions and the ability to carry heavier cargo. Instead of smaller packages, carriers can now carry larger items in the cabin. which they would have loaded in the belly, with the exception of hazardous materials.”

According to Kelly, each solution takes roughly the same amount of time to install as a seat. “The seat- and floor-mounted systems will be slightly faster. There is no fixed time, because it would depend on the number of individuals performing the task, but it is a similar process to installing a typical economy-class seat,” he said.

All four solutions are certifiable for any aircraft and/or aircraft seats. Kelly explained, “We can certify them based on their connection to the seatbelt attachment or seat track, or a combination thereof.” Assuming there are no unexpected supply chain disruptions, HAECO predicts it will need just over a month from the time of order to delivery, and the supplemental type certificates for each aircraft type will be developed during this time. “This is designed to be a short lead-time product using existing technologies which we know we could ramp up quickly,” he added.