John Horsfall Advances Sustainable Airline Textiles

Share

Speaking with APEX Media at IFSA Global EXPO in Long Beach, John Horsfall’s Global Business Development Manager Ellie Parkes detailed how the textile manufacturer addresses airlines’ growing focus on sustainable cabin products while maintaining passenger comfort.

American Airlines Partnership

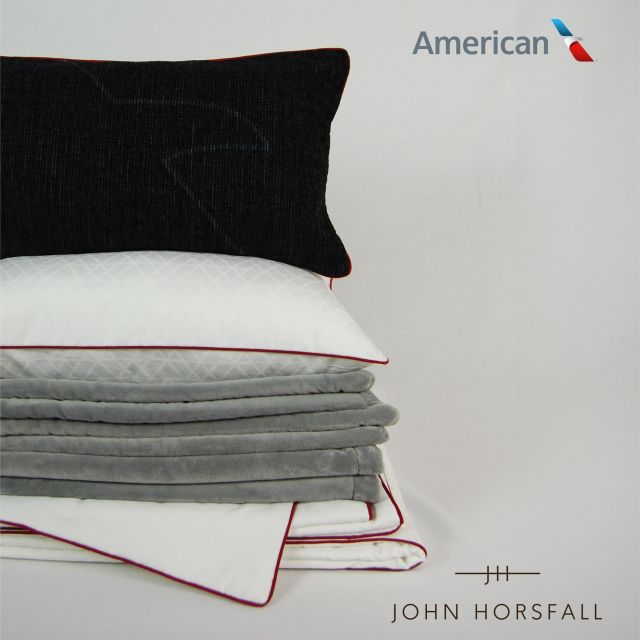

A major development for the company is its new bedding collection for American Airlines, which launched in May 2024. The collection spans multiple cabin classes, including Flagship® First, Flagship® Business, and Premium Economy, across more than 300 international and transcontinental flights.

“We make all the Flagship First and Flagship Business products,” Parkes said. The collection includes a dual-sided bolstered cushion featuring American’s eagle logo for first-class passengers. “Inside, you’ve got a dual-purpose, two-sided cushion. It’s memory foam on one side and fiberfill on the other, giving the passenger more opportunity to customise the space.”

Meanwhile, the premium economy blanket exemplifies the company’s approach to sustainable materials. “It’s 100% polyester, so it washes really well. It launders at low temperatures, and it dries quickly. It’s made with 50% recycled fibre,” Parkes explained. We chose 50% rather than 100% because when we blend 50% with 50% virgin fibre, it lasts longer.”

Sustainability and Product Longevity

The company’s ReThread® brand represents their sustainably sourced products, primarily using recycled polyester from post-consumer waste.

“When it comes to things like rotable versus disposable, both with textiles and catering product as well, there’s that real fine balance between what’s more sustainable – washing this thing 50 times and all the water and manpower and electricity that goes into washing it, or having something which we use once and we throw away,” Parkes noted.

Product durability presents unique challenges in the procurement process. “Sometimes it’s difficult for the people we’re selling to in the airlines to quantify, to make a business case for that, because they see the item price,” Parkes said. “They think, ‘That’s 50% more expensive than this fleece blanket.’ But actually, it will last at least 50% longer.”

Airline-Specific Designs

The company has a track record of working with airlines worldwide.

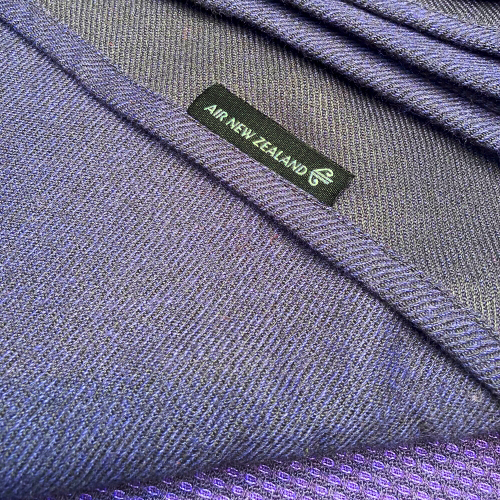

For example, the Air New Zealand blanket demonstrates their attention to airline-specific design requirements. “It’s got a really bright purple through it, and that picks up on the seat fabric as well,” Parkes said. “When it’s on the seat, it really picks up the colours.”

For SWISS’s new business-class product, they took a different approach. “Very, very sort of pared down, subtle design,” Parkes explained. “They’ve got the checked seat covers on SWISS, so they’ve got a lot of design in the seat itself. So this is kind of pared down.”

Material Innovations

The company continues to explore new sustainable materials. “One of those is unbleached cotton,” Parkes said. “It’s got what you might have used to have thought of as impurities in it. But I think part of the sustainability story is that people want to see natural fibres.”

Another innovation combines recycled materials from multiple sources. “The polyester is recycled from plastic waste, and the cotton is reclaimed from the garment industry,” Parkes explained. That’s taking essentially sort of waste scraps from the denim industry, collecting them, re-spinning them into yarn, and then blending them with the polyester for some strength.”

Communication of Sustainability Efforts

Parkes emphasised the importance of communicating sustainability credentials to passengers. “It’s not good enough to do something with the material. If you want it to be part of why they choose to fly with you, you must tell them that it’s there.”

The company achieves this through product labelling that includes specific environmental impact information.

For example, blanket tags indicate the equivalent number of plastic bottles used in their production, providing passengers with tangible reference points for the product’s environmental impact.