100 Solutions to Pandemic Problems, Part 4: Aircraft Interiors

Share

In the face of one of the biggest challenges ever to hit the aviation industry, companies responded swiftly. A multitude of seating partitions, sanitization solutions and robots are ready to fight COVID-19 in the cabin.

View all categories

Adhetec – Antimicrobial Adhesives

In July, Adhetec launched a series of customizable adhesive films for tray tables, in-flight entertainment (IFE) screens, armrests, handles and seat shells. The adhesive expert partnered with Pylote, which provided the antimicrobial technology. In lab tests, surfaces covered in the adhesive film for one hour demonstrated a reduction in viral load of more than 90 percent. Corsair began testing the product in September.

Aero Biotek – Biotek Shield

The sister organization of cabin lighting and manufacturing company PWI is designing a device that will shine UVC light in an aircraft’s ventilation system and neutralize viruses in the process. The first iteration of the product is being designed for Boeing 737 aircraft.

Aerofoam Industries – The Sentinel

This aerospace manufacturing firm based in California unveiled a seat-blocking console that is secured using the seat belt. It can be fitted with a clear, removable plastic divider to provide a barrier between seats. The Sentinel also offers cupholders and recessed compartments for passengers.

Allied BioScience – SurfaceWise2

This antiviral protectant can kill new germs that are deposited onto surfaces post-application. In the coming months, American Airlines will begin applying SurfaceWise2 via electrostatic spray across its entire fleet.

Autostop Aviation – Personal Protection Windows

This Serbian company is manufacturing acrylic-glass dividers to be installed between seats. The tall, thin barriers are widest at head level. German charter Private Wings was the first operator to order the product.

Aveo Engineering – VeoLite

This ultraviolet (UV) disinfection system runs the spectrum. When the cabin or cockpit is vacant, it uses UVC light to neutralize pathogens; when the aircraft is occupied, it emits UVA light, which continues to sanitize without posing a safety risk to humans. VeoLite is being distributed worldwide.

Aviation Clean Air and International Aero Engineering – Ion Distribution Unit for Ground Use Only

The electrons released by this ionization unit in the span of one to two hours can kill pathogens, sterilize bacteria and remove odor in the cabin. The duo of companies has had to increase production rates to keep up with demand for this portable, plug-in system.

Aviation Glass – AeroGlassShield

These rectangular screens installed between seats are made of AeroGlass, a lightweight, scratch-resistant and fireproof polycarbonate. The company is in the midst of getting the product approved and hopes to release it this year.

AviationRFI – Dual Seat Cover

Made from PPE medical fabric, this solution reduces the risk of germs being transferred from aircraft seats to clothing. The company claims the seat covers are recyclable. AviationRFI produces a double-sided version of the cover that can fit car seats when reversed.

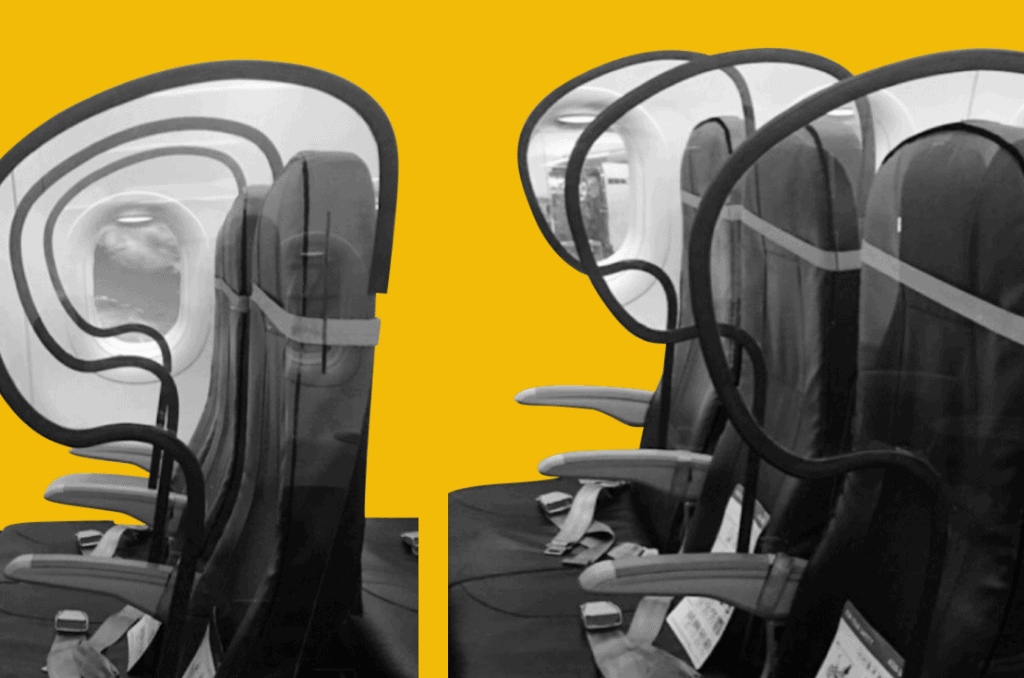

Aviointeriors – Glassafe

Aviointeriors released this shield that can be installed on existing seats to provide a partial enclosure around each passenger’s head. It can easily be installed and removed, while leaving tray tables, magazine pockets, coat hooks and other accessories free from obstruction.

Boeing – UV Sanitization Wand

The airframer adapted its UVC lavatory light technology to create this handheld unit, which will be manufactured in the US by Healthe and Far UV Technologies. During this year’s ecoDemonstrator tests, the wand disinfected the flight deck of an Etihad Airways Boeing 787-10 in 15 minutes.

Boltaron – Boltaron 9815N

Anticipating an uptick in the use of UV disinfection in the cabin, the thermoplastics company devised a material that can better withstand radiation. The product was exposed to six years’ worth of UVC light to prove

that the color, texture or structural integrity of aircraft seat parts made from it would not be affected.

Collins Aerospace – Touchless Lavatory

Next spring, Collins will finalize and apply for certification of an entire suite of touchless lavatory features, making toilet seats, flush mechanisms, soap dispensers, faucets and trash flaps more sanitary. The company says industrial design is being considered from the get-go, ensuring airlines receive distinctive products that help differentiate their brand.

Diehl – Portable Clean Light

For controlled disinfection and high efficiency, Diehl is developing a Portable UVC Light Unit that is optimized for use in the lavatory. The unit will function independently of aircraft type or platform and can be integrated into various lavatory layouts. For sanitization, the portable handheld unit is quickly and easily attached to a wall mounting plate.

Diehl – Touchless Lavatory

Sensors and actuators make many of Diehl’s new lavatory fixtures touchless. The waste flap, water faucet, toilet seat and lid, door lock and more can be activated with a wave of the hand, which increases passenger confidence, accessibility and ease of use.

EarthBay – PlanBay

This patent-pending kit blocks middle seats without the need to modify them. It consists of a console that supports two clear protection panels, forming a T shape. One separates passengers sitting on either end while the other runs along the tops of the seats. It also features lateral headrests.

Etihad Engineering – Seat Partitions

One of the solutions developed by Etihad’s maintenance and engineering arm is a line of middle-seat blockers suitable for all commercial Airbus and Boeing aircraft. Options include a partition that stretches across the seat and hooks onto the armrests, a seat box and panels placed in between each headrest that provide separation.

Expleo – Separated Care Area

Airline crew can create a quarantine area in the last three rows of seats in a couple of minutes without special tools. Expleo’s made-in-Germany kit includes a set of crew rest couches and curtains that can be adapted for double- or quadruple-seat layouts.

Factorydesign – HeadZone

This fold-out panel was conceived as a portable barrier for short-haul routes on seats without IFE systems. It’s made from recyclable materials and can be ordered in a variety of colors. The rear-facing panel offers the potential for sponsored branding and advertising.

Flitetec – MX14 Aero

The company released this antibacterial stain remover as the coronavirus pandemic intensified in March. It is water-based and safe to use on leather, soft furnishings and polycarbonate surfaces.

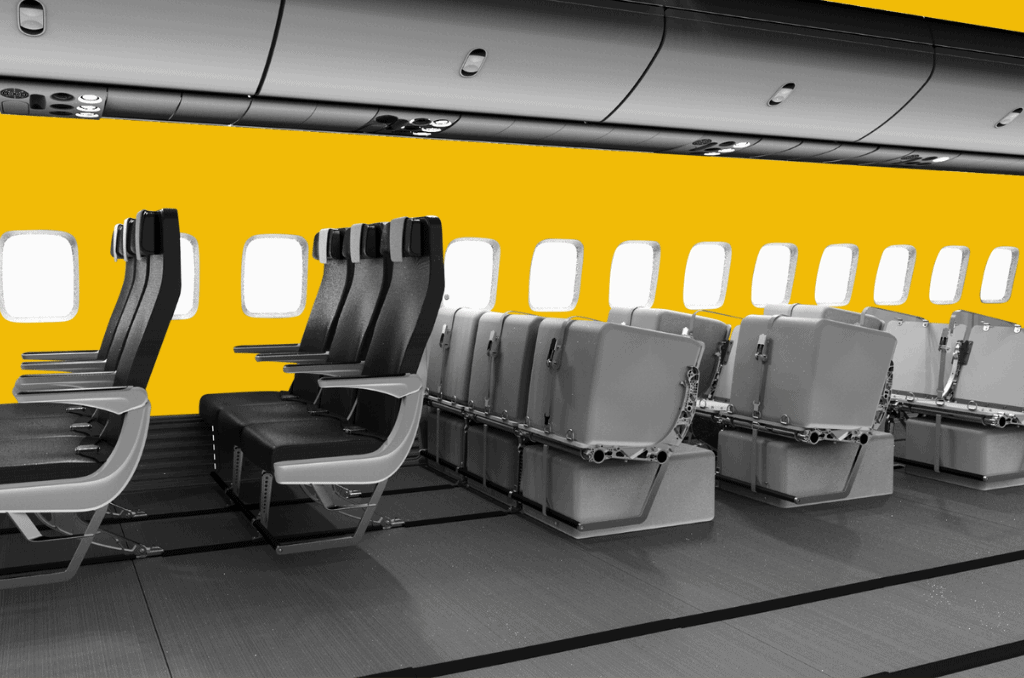

Haeco Cabin Solutions – Mixed Main Cabin Solutions

Airlines looking to operate flights that carry both passengers and cargo on the main deck now can thanks to Haeco’s four cabin solutions. The In-Seat Stowage and Seat-Front Stowage systems allow seats to remain in place, while the All-in-One Package and Pallet Stowage solutions are full-cargo options.

Hecosol – Titano

Lufthansa Technik announced in June that this long-lasting virucide was on its radar. Titano is applied electrostatically and sticks to surfaces, killing most viruses for up to one year. Lufthansa Technik wants to determine how it interacts with overhead bins, tray tables, armrests and sidewalls.

Honeywell – UV Cabin System

Dimer’s GermFalcon was met with limited interest when it was introduced in 2013 – then COVID-19 hit. Honeywell announced an exclusive strategic business relationship with the company in June, and by the end of September Qatar Airways had acquired six units. The battery-operated device can disinfect an Airbus A320 in 10 minutes.

Jamco America – Soft Divider

This leather-wrapped cabin class divider offers a larger partition in response to the desire for barriers between passengers. Designed for single-aisle aircraft, the divider is flexible enough to allow seats to recline and can feature custom branding. It is certified for the Boeing 737 and is scheduled to be certified for the Airbus A321 later this year.

Kaze – Sunburst UV Bot

This Singaporean robot can be used in airports and by the aviation sector in general, according to the company. Once it has a route mapped, it wheels around automatically and disinfects spaces thanks to a large UVC lamp protruding from its base.

Lufthansa Technik – Headrest Divider

This polycarbonate seat divider is inserted in the magazine compartment of the middle seat and then latched onto the table mounting. One shipset can be installed within a few hours. Lufthansa Technik has begun the process of acquiring a supplemental type certificate for this product.

Lufthansa Technik – UVC Mobile Lamp

In China, aircraft lavatories must now be disinfected every four hours or after every tenth usage. This lamp makes the process quicker and safer for crew: It uses UVC light to neutralize pathogens in 44 seconds. The product comes in wired or wireless versions.

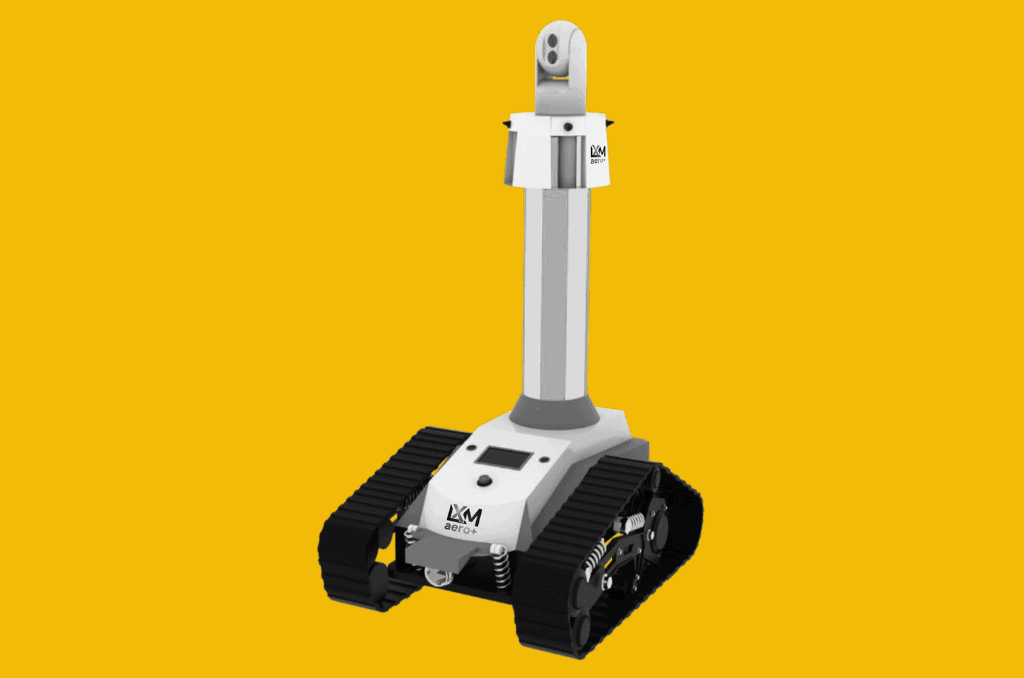

LXM – LXMRobot

LXMRobot disinfects the cabin by shining UVC light. It’s controlled via an app, but once it gets to a designated area, it moves autonomously. This sanitization robot can be used in airports as well.

MGR Foamtex – MGRSafeWall

MGR Foamtex’s new magnetic cabin panel combats the coronavirus thanks to built-in Biomaster antimicrobial technology. The panel is made from dual-density foam that is up to 60 percent lighter than traditional versions. It also deadens noise and comes in a wide variety of decorative finishes.

Safran – Travel Safe

This patented suite of solutions, released in June, includes a removable seat partition called Ringfence, pedal-operated seat recliners and a range of disinfectant coatings for seats and tray tables.

Signature Plating – Antimicrobial Clearcoat

This full-service plating facility is using a new clearcoat finish for metal parts that incorporates an antibacterial additive. It neutralizes pathogens that come into contact with the treated surface, reducing the spread of germs.

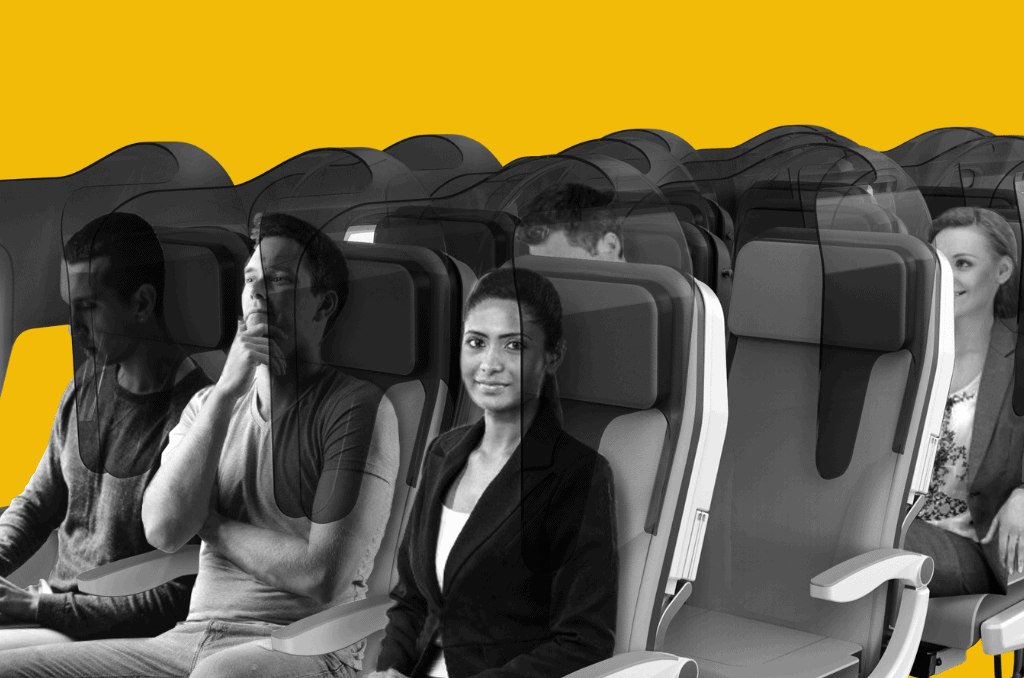

Tapis, Boltaron, Molon Labe Seating – Aircraft Seat Proposal

Three companies came together and combined their expertise to draw up plans for a seat that addresses passenger concerns in the COVID-19 era. The design, expected to be completed by 2021, makes use of Molon Labe Seating’s staggered S2 economy-class seat with headrest barriers, Boltaron 9815N thermoplastic and Tapis’ antimicrobial PromessaAV Ultrafabrics for the seat covering.

Teague – AirShield

Teague studied airflow patterns in the cabin and concluded that water-vapor droplets resulting from an unguarded sneeze can reach adjacent passengers. Its solution is a 3-D printed component that fits over overhead vents, diverting droplets toward the floor.

Tenerías Omega – Fresco and Rocket

This Spanish tannery developed two ranges of antibacterial leather called Fresco and Rocket. To prevent bacteria from collecting in the material, the company applies special coatings during production. The final product does not contain chlorine or bleach.

Vision Systems – Barrier

Pivoting from shading systems to seat barriers, Vision Systems released a transparent, armrest-mounted screen that protects passengers at each seat. The product can be ordered in any size or shape and is treated with an antibacterial finish.

Vshieldco – Vshield

By carrying a Vshield stick, airline staff and frequent flyers can protect themselves from disease. The product releases chlorine dioxide vapor that deactivates viruses and bacteria over a 108-square-foot radius for 45 days.

“100 Solutions to Pandemic Problems” was originally published in the 10.4 November/December issue of APEX Experience magazine.