John Horsfall and the importance of in-cabin sustainability

Share

UK textiles company John Horsfall has been a family owned business for six generations. In the 1970s it moved into the airline business, which is now where the company is exclusively focused, making textile based products ranging from blankets to pillows to mattress pads.

In addition to being a finalist in the APEX/IFSA awards, John Horsfall is exhibiting at EXPO this year, showcasing a number of products including the sustainable ‘Re-Thread’ range. APEX Media talked to the John Horsfall team to find out more.

In-cabin sustainability is only a small part of the airline sustainability puzzle, but from the passenger’s point of view, it’s the most visible. It is what s/he sees and can experience.

“It’s important that the customer knows that the airline is working towards a sustainability story”, said John Horsfall’s design manager Alexandra Allen. “What happens in the cabin is what they see, and that in turn gives them the idea that there are other things going on in the background.”

Essentially, in-cabin sustainability can act as a very visible sign that an airline is serious about sustainability, and John Horsfall has been trying to give airline customers a way to showcase that.

John Horsfall had in fact been making products from recycled materials for eight years, but the company’s sustainability efforts stepped up a gear during COVID.

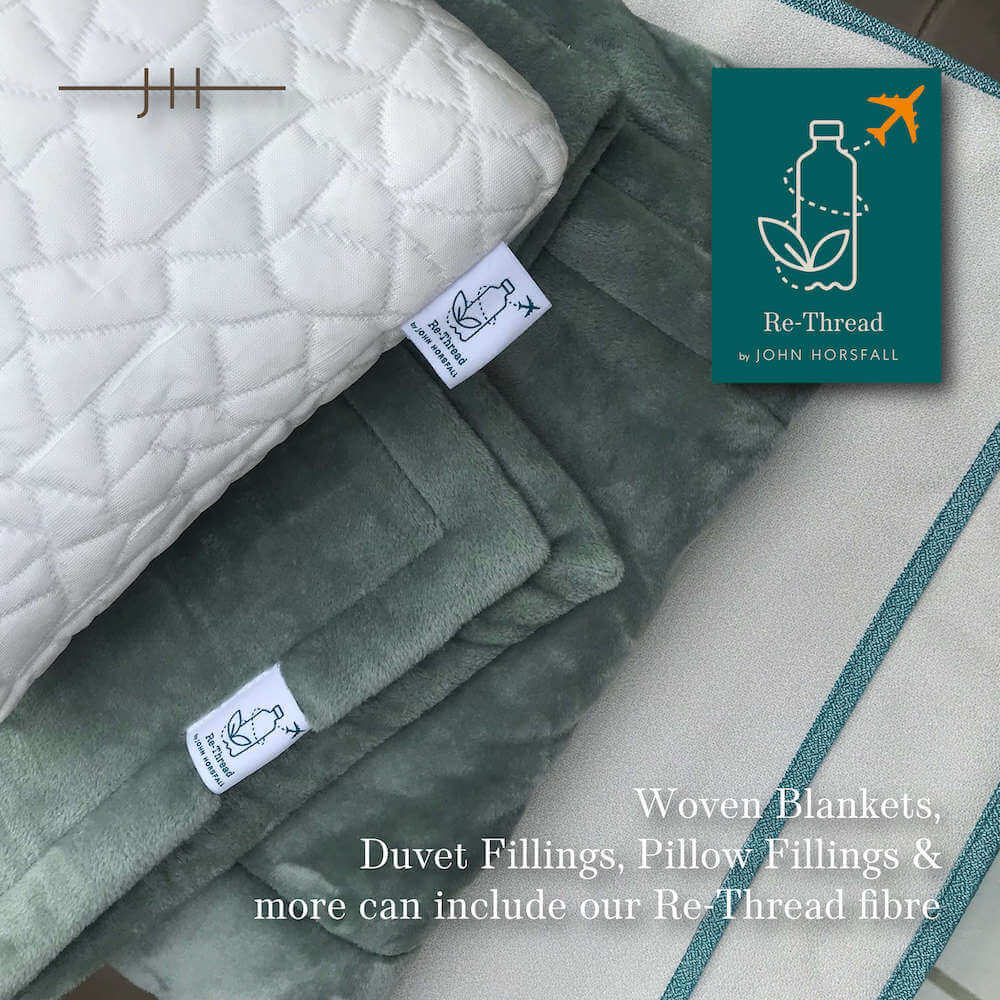

Business development manager Ellie Parkes told APEX Media that it was during that time, that the company decided to highlight the fact that they had products which were GRS (Global Recycle Standard) certified and to put them under a new brand umbrella called ‘Re-Thread’, given that few consumers know what GRS is.

“Re-Thread is our in-house brand that we’ve trademarked, and we did that as it’s a marketing tool for us, but also it’s a marketing tool we can offer our customers. It’s really recognisable and it is a very easy sign-post to customers and passengers that this has been recycled, that it has an element of sustainability to it.”

Ellie Parkes admitted that, “We’re not going to fix everything with a recycled blanket but from a passenger point of view, it’s something consumers are more and more used to seeing and expect to see.” This comes as there is a move to eliminate single use plastics from the consumer supply chain, with airlines themselves being engaged in plastic elimination initiatives.

The Re-Thread range includes materials made from either partially or wholly with recycled fibres. It also includes women blankets made with ‘rpets’, recycled polyester made from waste plastic, and products made with regenerated cotton (from waste garments).

The final part of the Re-thread story however is to make products from bio fibres. These are plant based alternatives to the polypropylene textiles, made from plastic. These type of blankets have been common in economy cabins, and so John Horsfall is trying to offer airlines a more sustainable alternative.

Ellie Parkes admitted that as with a lot of sustainable products, there is still a green price premium attached to them, but one airline is currently trailing these new bio fibre based products.

Overall, the company has seen a huge upturn in business since COVID travel restrictions came down. In addition to working for airlines such as Air Mauritius and British Airways for decades, new customer airlines have since come on board.

You can visit John Horsfall at the APEX/IFSA EXPO to find out more about the Re-Thread range and other products in the company’s portfolio. They are also nominated for the work they did for Finnair at the APEX/IFSA Awards, with the winners announced on Wednesday evening.