Seat as Honey: Nature-Inspired Comfort Solutions Are All the Buzz

Share

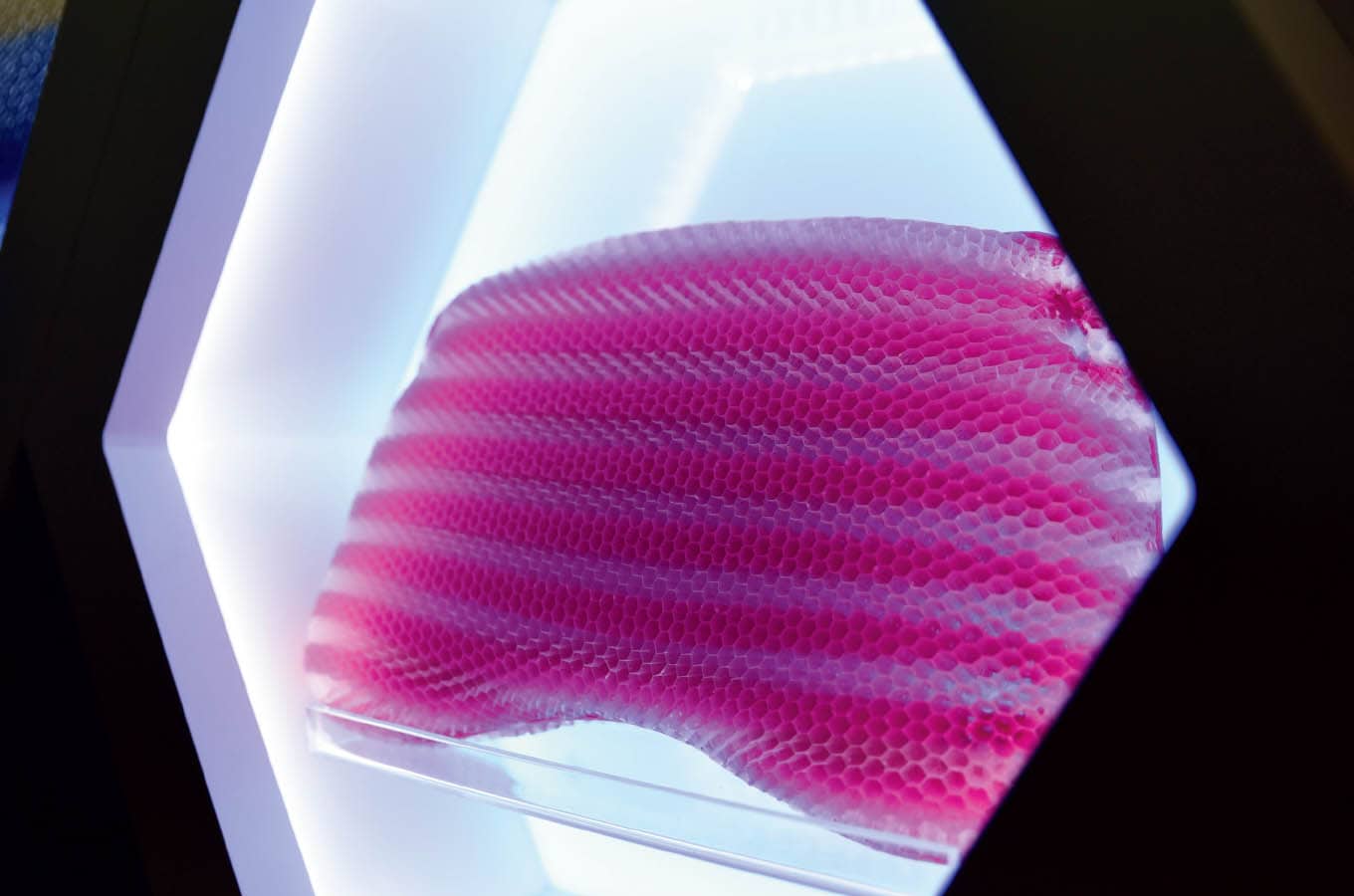

APEX Insight: Seat padding with a honeycomb structure hits the sweet spot with airlines looking for durable, eco-friendly comfort solutions.

The first application of Supracor’s energy-absorbing honeycomb technology was to the midsole of Reebok’s athletic shoes in 1988. The flexible honeycomb product has since been used in Disney’s and Universal Studios’ bumper car rides, for wheelchair cushions and now on airplanes.

Silicon Valley-based Supracor made its name in the aerospace industry as a finalist at the 2012 Crystal Cabin Award ceremony. Although the company didn’t bring home a trophy, it did distribute some sample cushions to prospective clients, including Swiss International Air Lines. “I didn’t hear from SWISS for a couple of years,” Susan Wilson, vice-president and creative director of Supracor, recalls. “Then one day, I got an e-mail saying, ‘Wow, you’re right – It’s really comfortable! I’ve been sitting on it for two years now.'”

“The cushion helps to circulate air and evaporate moisture, so you never get the heat buildup from sitting for a long time.” – Susan Wilson, Supracor

SWISS became the launch customer of Supracor’s Stimulite cushions in 2016, when the airline installed them in the economy cabin of its Boeing 777s. The cushions will soon be retrofitted in the economy, premium economy and first-class cabins of the airline’s Airbus A340s, as well. According to Wilson, “The cushion helps to circulate air and evaporate moisture, so you never get the heat buildup from sitting for a long time.”

The thermoplastic material is naturally antibacterial and durable, Wilson explains, making it perfect for the spill-prone in-flight environment. “If somebody spills coffee or wine, typically what happens with foam cushions – because they can’t be washed – is they are replaced and end up in landfills,” she says. Supracor’s cushions can be cleaned dozens of times and are completely recyclable.

Slovenia-based Vanema similarly draws on the honeycomb structure for its Octaspring technology, foam springs that can be placed to create varied density zones. “Octaspring is incredibly adaptable and customizable,” Sandi Cesko, chairperson of Vanema, says. “The springs can be made in a wide range of densities, allowing manufacturers to create targeted firmness zones and properly support high-pressure points that can become a nuisance on long-haul flights.”

Like Supracor, Vanema’s relationship with nature doesn’t end with the inspiration it draws from it. The company is working on prolonging the life cycle of its product – for example, by cutting up the foam springs and using them for carpeting – in an effort to reduce its long-term environmental impact.

“Seat as Honey” was originally published in the 7.5 December/January issue of APEX Experience magazine.