Dreamliner Cabin Pressure Tech Reduces Altitude Sickness, Benefits PaxEx

Share

This article originally appeared in The Innovation Issue of APEX Experience.

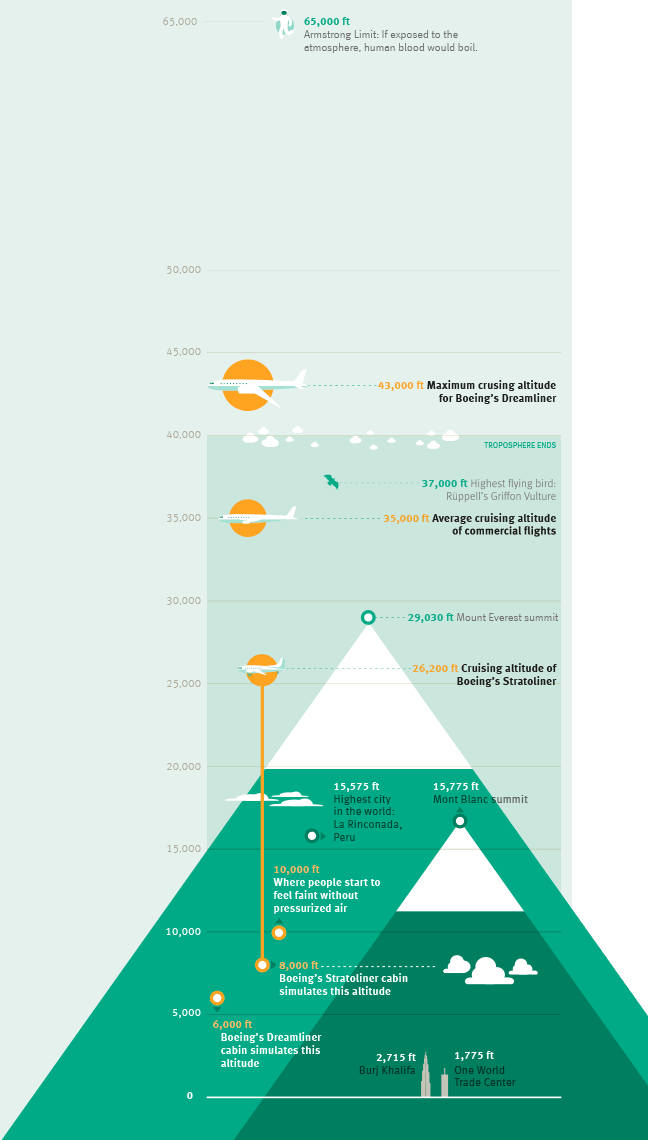

APEX Insight: Cabin pressure is something many passengers don’t consider except when their ears pop on takeoff and arrival – but it’s crucial to air travel. Without it, we wouldn’t be able to fly much higher than 10,000 feet. In a move to make air transit more pleasant, companies like Boeing are designing new airplanes that are strong enough to sustain lower cabin pressures at high elevation, without risking structural damage.

Cabin pressurization debuted in passenger airplanes shortly before World War II and is achieved as a partial byproduct of the process of jet propulsion. Cold air cycles through the jet engines where it is superheated and pressurized. The hot air is then cooled with cold air from outside the airplane before being pumped into the cabin for passengers and crew to breathe.

The internal pressure of a typical aluminum passenger airplane during long-haul flights simulates a height of 7,500-8,000 feet at maximum elevation (averaging around 35,000 feet), below the point at which the human body can no longer safely tolerate the low atmospheric pressure, but still at a level where people can experience symptoms of altitude sickness.

The Boeing 787 Dreamliner is the first passenger jet airliner built from carbon fiber reinforced plastic.

In a move to make air transit more pleasant, companies like Boeing are designing new airplanes that are strong enough to sustain lower cabin pressures at high elevation, without risking structural damage. The Boeing 787 Dreamliner is the first passenger jet airliner built from carbon fiber reinforced plastic. Thanks to the strong, lightweight polymers making up almost 50 percent of the Dreamliner’s body, the airplane is capable of sustaining higher internal pressure than aluminum aircraft at equivalent altitudes.

The Dreamliner’s cabin pressure simulates an elevation of just 6,000 feet, a 20 percent reduction over similar aircraft. This has tremendous benefits for the passenger experience. According to statistics from Boeing, just five percent of passengers struggle with “respiratory distress” in the Dreamliner, versus one in four passengers traveling in more conventional airplanes on flights of 12 hours or more.