As the air travel industry confronts the climate crisis, can biology show the way to a more sustainable future?

During about the same time Leonardo da Vinci painted the Mona Lisa, he compiled the Codex on the Flight of Birds, chronicling his grasp of avian flight and building on prior ideas for a human-operated flying machine. It wasn’t until about 400 years later, though, that the Wright brothers, also emboldened by their observations of the feathered creatures, would become the first to successfully take flight.

In the 116 years since, we’ve somehow deviated, gone from revering and emulating nature to adopting anthropocentric practices that pose a threat to it. Air travel alone accounts for about two percent of global carbon dioxide (CO‚‚) emissions, and recent studies show that non-CO‚‚ pollutants, such as nitrogen oxide and contrails, also have a significant climate impact. Faced with social, ethical and regulatory pressures, airlines have no choice but to ask, “Can we be doing better?”

The answer – most can agree at this point – is yes, and a growing community of engineers, scientists and designers are pivoting once more to nature as a template, this time to work toward more balanced economies of energy and material. Advances in technology mean that rather than just mimicking organisms (and microorganism, such as yeast, bacteria, fungi and algae), we can now integrate them into products and processes operating in tandem – not tension – with ecological preservation.

The answer – most can agree at this point – is yes, and a growing community of engineers, scientists and designers are pivoting once more to nature as a template, this time to work toward more balanced economies of energy and material. Advances in technology mean that rather than just mimicking organisms (and microorganism, such as yeast, bacteria, fungi and algae), we can now integrate them into products and processes operating in tandem – not tension – with ecological preservation.

In adjacent industries, that’s meant developing textiles made from lab-grown collagen and colored with bacterial pigment, and filling automobile tires with living moss whose natural photosynthesis process powers onboard electronics. These innovations are the result of the emerging fields of biodesign, bioengineering and synthetic biology (often referred to interchangeably), whose proponents believe cross-pollinating nature and science with other disciplines is the way to a more sustainable existence.

FUELING THE BIOECONOMY

The synthetic-biology market is expected to amount to $17.36 billion by 2026, according to a study by Reports and Data, with its reach extending to medicine, cosmetics, fashion and, yes, even aviation. Virgin Atlantic, for one, is harnessing one of biology’s many recent applications for the area where, airline PR specialist Jessica Cross Brown says, it can have the biggest impact: “As an airline, that will always be our fuel.”

Plant-based biofuels have been around almost as long as cars, but it wasn’t until about a decade ago that the first flight partially powered by biofuel took place. And only in the last couple of years have airlines committed to exploring solutions that come from waste sources that do not compete with food security and land resources. Finding a fossil-fuel alternative that addresses these concerns led Virgin to LanzaTech, which Cross Brown calls “the first company we felt could meet our strict criteria for sustainable fuel while also being price-competitive.”

Chicago-based LanzaTech was founded in 2005 by two biologists looking for a feedstock that was abundant, low-cost and did not further add to food, land or water scarcity. “They arrived at the idea of waste and pollution. There’s a lot of it, that’s for sure. And if we could use it, that would be an amazing way to turn the global carbon crisis into an opportunity,” says Freya Burton, the company’s chief sustainability and people officer.

After sifting through a bacterial library in search of the best way to process carbon emissions – or gasified waste or residue such as landfill trash – they came across an ancient microbe originally isolated from the gut of a rabbit (though no actual rabbits were involved in the process), that was able to live off waste carbon and generate ethanol as a by-product. Ethanol can be used to make a variety of products, including plastics for everyday goods, synthetic fibers for things like sportswear and sneakers, and sustainable jet fuel.

“What we are doing is pretty much retrofitting a brewery onto the emission source. We put our site onto the existing footprint, and instead of the gas being combusted and going back into the atmosphere as CO‚‚, we feed it straight into our bioreactor,” Burton explains, adding that the company’s first pilot plant saw bioreactors retrofitted to a local steel mill outside of Auckland, New Zealand, where the company originally hails from.

LanzaTech has since secured funding for five commercial ethanol plants, in China, Belgium, the US, India and South Africa, and with Virgin Atlantic celebrated its first commercial flight in October 2018. A few months prior, the UK government awarded LanzaTech a £410,000 ($532,000 US) Future Fuels for Flight and Freight grant to determine the feasibility of building a 40- to 50-million-gallon jet fuel plant in Britain. Once LanzaTech’s carbon-recycling fuel is recognized by the Renewable Transport Fuel Obligation – the country’s existing biofuel incentive program – Cross Brown says it “could be up and running, creating commercial volumes of their fuels in the UK by the early 2020s.”

THE MOST POWERFUL TECHNOLOGY AROUND

While airlines are looking to bio-based fuel alternatives, airplane manufacturers are considering designs that favor efficiency, weight savings and a reduction in fuel burn. In recent years, there has been a shift from steel and other metals to lighter carbon-fiber-reinforced polymer composites for aircraft parts, but these can be energy-intensive to produce, difficult to recycle and rigid (the last of which may sound positive in the context of aircraft fuselage, but can be a drawback when it comes to parts of the aircraft that are prone to bird strikes, for example, for which flexibility can help with shock resistance).

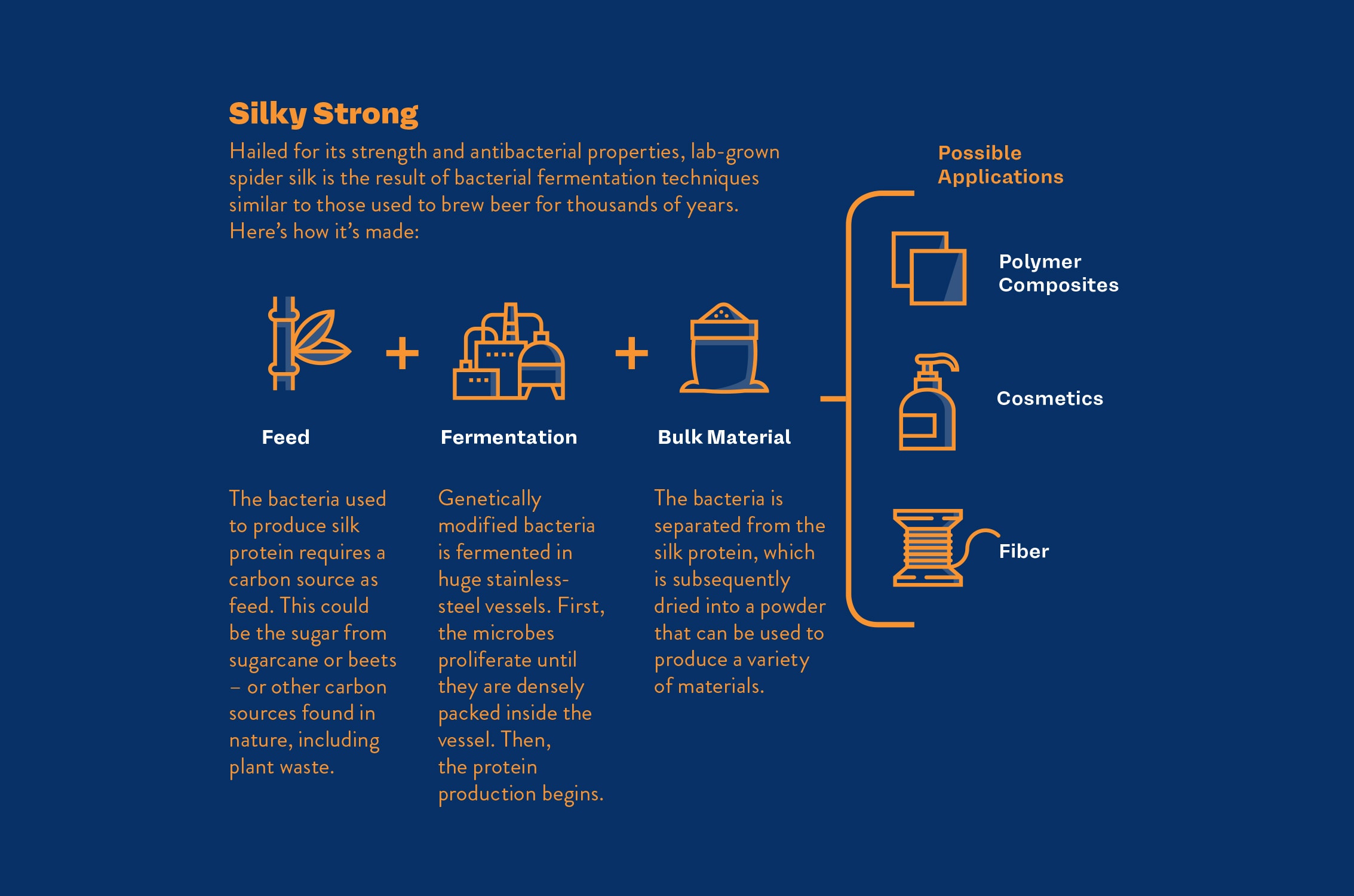

Looking for another way, in 2017, Airbus approached Munich-based AMSilk, one of several companies working to commercialize lab-grown spider silk, to collaborate on a composite material that could be used for aircraft parts. Best known for creating the first 100 percent-biodegradable running shoes with Adidas, the German bioengineering firm uses traditional fermentation techniques to feed a genetically modified E. coli bacteria to produce a vegan spider-silk fiber it calls Biosteel – without the crawlies.

So far, AMSilk’s main business has come from selling the silk to cosmetics companies for skincare products and shampoo, but its CEO, Jens Klein, says the polymer industry stands to benefit, too. “Historically, in the polymer industry, there has been this impossible dilemma: Do we choose high-performing materials or ones that are good for the environment? We are working toward a future in which companies like Airbus no longer have to choose between the two.”

The airframer is currently in the process of coupon-manufacturing the material, said to be five times tougher than steel, and Klein says airlines stand to benefit from other applications, including spider-silk seat covers and other composites inside the cabin. “Biology is the most powerful technology in the world. And we are constantly evaluating new market applications of Biosteel – where the material is not just the sustainable option, it is the best option.”

Biological exploration isn’t a one-off for Airbus, which in 2015 partnered with The Living, an architecture studio that embeds living organisms into its design processes, to rethink the load-bearing partition that separates the crew workstation from the rest of the cabin. In this case, biology determined the software’s architecture, not the building material itself, with the naturally recurring patterns of slime mold and bone growth defining the algorithm for the design. The result is a seemingly random web-like pattern using minimal material but optimized for load bearing just the same. Airbus’ standard partitions weigh 143 pounds; The Living’s clocked in at 66.

SOLUTIONS A-BREWING

Jet fuel and hefty airplane parts are the obvious contenders for biological retuning, but Kit McDonnell, manager of Capital Markets and Special Projects at Ginkgo Bioworks, advises air travel stakeholders to apply a more comprehensive approach. “In the airline industry, there are a lot of different aspects of sustainability that are not being addressed right now. Fuel has a really big environmental impact, but biology can be a credible avenue for so much more – the materials being used in airplanes, building materials for airports, air filtration, textiles, single-use packaging in the cabin and even electronics. Really, every aspect of the airport and airline experience can benefit from thinking about incorporating biology,” she says.

Ginkgo is a Boston-based, industry-agnostic microorganism design foundry that manipulates DNA sequences of living organisms for the desired results of its clients. As of mid-September, it boasts a total funding of $719 million, and has inked deals to produce cannabinoids, discover new antibiotics and accelerate the development of living medicines. Just this year it launched Motif FoodWorks in an effort to address the need for better alternative proteins. “We want to enable more companies like Impossible Foods to exist, so we are making those key ingredients for bio-based foods – and they can definitely be used ubiquitously in the airline industry,” McDonnell says.

In July 2018, Air New Zealand became the first to serve a meal of this kind, with the Impossible Burger being introduced in the Business Premier cabin on its Los Angeles-Auckland route. “We had been following Impossible Foods for some time and had been impressed with the work it’s doing, and saw an opportunity to work together and take the burger to the skies for the first time,” an airline spokesperson says, adding that the burger was being served on Los Angeles-London flights until October 2019.

The Impossible Burger looks, smells and tastes like meat, thanks to an iron-containing molecule called heme, which can be found in the root of soy plants. The heme in the Impossible Burger is similar to that found in animal meat, but requires 87 percent less water and 96 percent less land to produce, and emits 89 percent less greenhouse gases.

Impossible Foods may have made its mark with its beef-like patty, but the company is also developing alternative-protein chicken, pork, lamb, dairy and fish. While Air New Zealand was unable to comment on expanding its bio-based menu, the spokesperson did say, “We are always looking at offering innovative product choices, and we will continue to do so in the future. Our products and experiences will continue to have a modern edge reflecting the needs of our customers.”

The airline has since been joined by Cathay Pacific, which offers the rival Beyond Meat burger in its first-class lounge at Hong Kong International Airport and, since October, a pasta dish with OmniPork, a meat substitute made from soy, shiitake mushrooms, rice and pea protein, created by Right Treat, a branch of environmental venture Green Monday. Other food tech companies, such as Perfect Day and Evocative, are looking at ways to modernize menus with ingredients like microorganism-made ice cream and bacon strips – without the environmental costs.

Another bio-based material gaining traction at the moment is mycelium, the thread-like root structure of fungi. Mycelium has already been used to produce compostable packaging for Dell and IKEA, to build a 40-foot-high, organic structure in the courtyard of MoMA PS1 (a project in collaboration with The Living, the same company behind Airbus’ partition) and as a leather replacement in fashion and furnishings.

Mitchell Joachim, co-founder of architecture and urban design research group Terreform ONE, says, “Mycelium is also an amazing replacement for what would be used for insulation, cushions, Styrofoam or any kind of seating element. It’s literally found in nature, and we can control it. We grow it in a mold, and it shapes itself in seven days.” In collaboration with community biology lab Genspace, Terreform ONE has developed a series of benches using the material.

Unlike most regular furniture that ends up in a landfill, mycelium-based furniture can be thrown into a garden, where it’ll compost for a few months and feed thousands of other life-forms. This, Joachim notes, would represent a massive shift in how we think about the industrial making of furniture, which is often designed for obsolescence. “No furniture at an airport will last forever – I don’t care who the manufacturer is. After 10 years or so, it’s being replaced with a new design. This fungus furniture would last the same 10 years, fitting into the existing system.”

Finding solutions that discreetly slip into the existing ecosystem could be airlines’ and airports’ best bet, Joachim says, especially given that the degradation of the planet has happened under similarly covert circumstances. “When I get into an airplane, I’m not thinking that this thing is some big, poisonous emission-belching factory that’s directly influencing how I breathe. It just doesn’t seem clear,” he says. “Jets are these super-sleek, beautiful things. Many of us use them despite the carbon ejected, the sourcing of the fuels, the materials used in them and all their embodied energy, which are all very real and have been slowly affecting the Earth for the better part of 100 years.”

Going forward, Joachim proposes adopting a “stealth green” model that doesn’t depend on radical, and unlikely, changes in human behavior. “Jets are a good thing – we aren’t going to throw them away overnight, and we should never do that,” he says. “But behind the scenes, in the background, operations could be engineered and architected to perform at incredible standards, maybe even cleaning the air instead of polluting it.” Living materials, for which sustainability is always already built in, present a promising way forward.

Then again, an extreme overhaul might be what extreme times like these require – and what consumer-cum-activists will come to demand. It’s not as speculative as one might think, LanzaTech’s Burton says, sharing an idea for a facility that simultaneously produces the material for the body of an aircraft, while emitting the carbon that’ll be transformed into jet fuel, as well as the seatbelts, fabrics and filling for the seating. “And after a flight, the trash accumulated could be converted back into packaging or utensils for the next. That’s the goal,” she says. “There’s a lot of interest for this type of circular model from the airlines who approach us – they would love that.” Thanks to an ancient microbe borne from the gut of a rabbit, it may not be so far off.

“A Living Matter” was originally published in the 9.5 December/January issue of APEX Experience magazine.